FOR YOUR VEHICLE

Ceramic Brake Pads: Is the Premium Upgrade Right for Your Car?

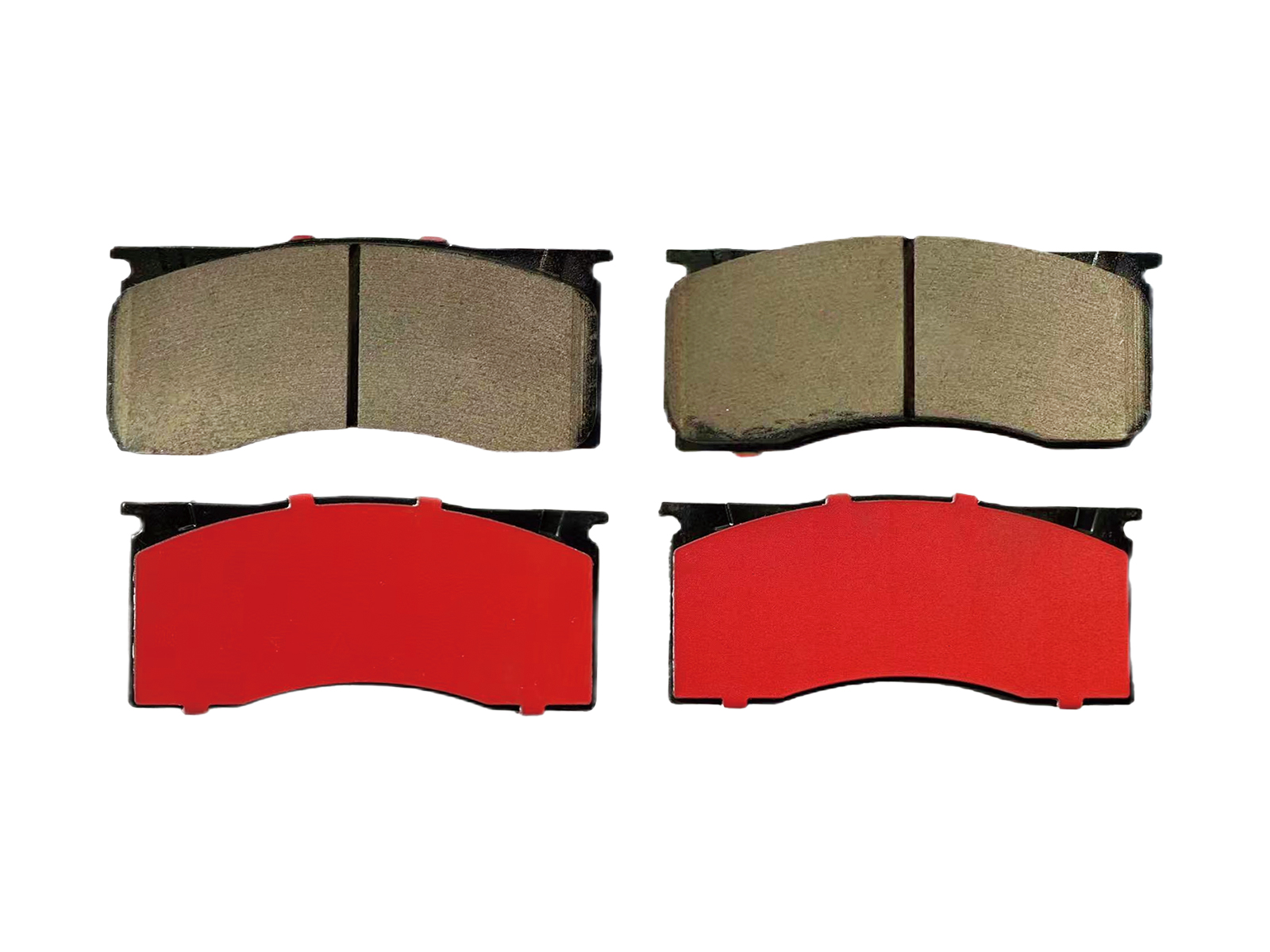

Ceramic brake pads aren't made from everyday pottery. They are a high-performance composite material engineered at high temperatures. Typically composed of ceramic fibers, various mineral fibers, and specific fillers, they are designed to offer superior braking characteristics.

Unlike traditional semi-metallic or low-metallic pads, ceramic formulas contain little to no metal fibers. This leads to core benefits: significantly reduced braking noise, less dust that doesn't rust onto wheels, and better protection for your brake rotors with reduced wear.

1. How They Work: The Technology

The innovation is in the materials. These pads are an advanced composite based on inorganic, non-metallic components.

Key ingredients include ceramic fibers (like alumina), aramid fibers, and other mineral fibers. By omitting rust-prone steel fibers and using specialized binders and friction modifiers, they achieve stable, metal-ceramic-like properties under heat. During braking, temperatures can reach 800-900°C (1472-1652°F), causing a sintering reaction on the pad's surface. This forms a stable, wear-resistant friction layer, unlike traditional pads that can melt or gasify and lose performance under extreme heat.

2. Performance Benefits

The advantages focus on comfort, durability, and heat stability.

First is superior comfort. The lack of hard metal fibers means quieter operation with minimal squealing. They also produce far less dust, keeping your wheels cleaner.

Second is excellent durability. Studies show ceramic-based pads have a much lower wear rate than traditional resin-based pads. In practice, their service life often exceeds that of standard semi-metallic pads by over 50%. They are also gentler on the brake rotors, indirectly extending the life of your entire brake system.

Finally, there's outstanding thermal stability (fade resistance). This is a key feature. While traditional pads can lose friction coefficient rapidly under repeated hard braking, ceramic pads resist this heat fade more effectively, maintaining consistent stopping power and a higher safety margin.

3. Potential Drawbacks & Considerations

It's important to understand the limitations. The primary barrier is cost; ceramic pads are typically priced significantly higher than standard metallic pads.

Some drivers note a different pedal feel. Certain ceramic pads can feel slightly "softer" during initial brake application, with a less aggressive initial bite compared to metallic pads. This linear response requires a brief adaptation.

There's also a common misconception about cold-weather performance. While some believe they are weaker in the cold, modern high-quality ceramic formulas perform well across temperature ranges. The bigger risk is product quality. The market has substandard pads with inadequate friction coefficients, compromising safety and leading to product recalls.

4. Who Should Buy Them & A Buying Guide

Ceramic pads aren't for everyone; they best suit specific needs.

They are ideal for drivers who prioritize comfort and a clean vehicle. If you hate brake noise and black wheel dust, they're a perfect choice. They also suit high-mileage drivers focused on long-term cost, as their extended life can offset the higher upfront price. For standard passenger cars and SUVs not under heavy load, they balance performance and comfort well.

When buying, put safety first. Always choose reputable brands from authorized sellers to avoid pads with substandard friction coefficients. Check the product's stated friction coefficient (e.g., 0.40, 0.42) and match it to your vehicle's requirements or professional advice. Owners of high-performance cars or those with higher demands might explore pads using even more advanced materials, like carbon fiber-silicon carbide composites.

5. The Future of the Industry

Ceramic brake pads represent a key direction in brake material evolution, moving toward smarter, more precise manufacturing.

Material development is merging with AI. Top manufacturers like Brembo now use systems (e.g., ALCHEMIX) to simulate and develop new friction formulas, slashing development time from days to minutes. In production, AI and 3D vision are becoming standard for quality control. Mandates for 100% inspection, like those enacted in some regions, are met with AI systems that boost defect detection rates and product reliability above 99%.

As technology improves and scales, the performance and value of ceramic brake pads are likely to increase, making them accessible to more drivers.

Remember: Brake pads are a critical safety item. Replace them immediately if you hear the wear indicator screeching (a metal tab contacting the rotor at ~2-3mm thickness) or if your dashboard warning light illuminates. Don't rely on feel alone; have a technician check the pad thickness through the wheel spokes regularly for peace of mind.