FOR YOUR VEHICLE

Ceramic or Metallic Brake Pads: A Straightforward Comparison

At your next service, when asked "ceramic or metallic?" it's easy to hesitate. The promise of "quiet" and "durable" ceramics comes with a higher price, while "strong-performing" metallics raise concerns about noise and wear. This choice affects your daily comfort, long-term costs, and safety.

Let's skip the jargon. We'll directly compare what matters most: noise, dust, brake feel, lifespan, and price to find the best match for your driving.

1. Daily Feel: Noise & Dust

Your ears and wheels will notice the difference first.

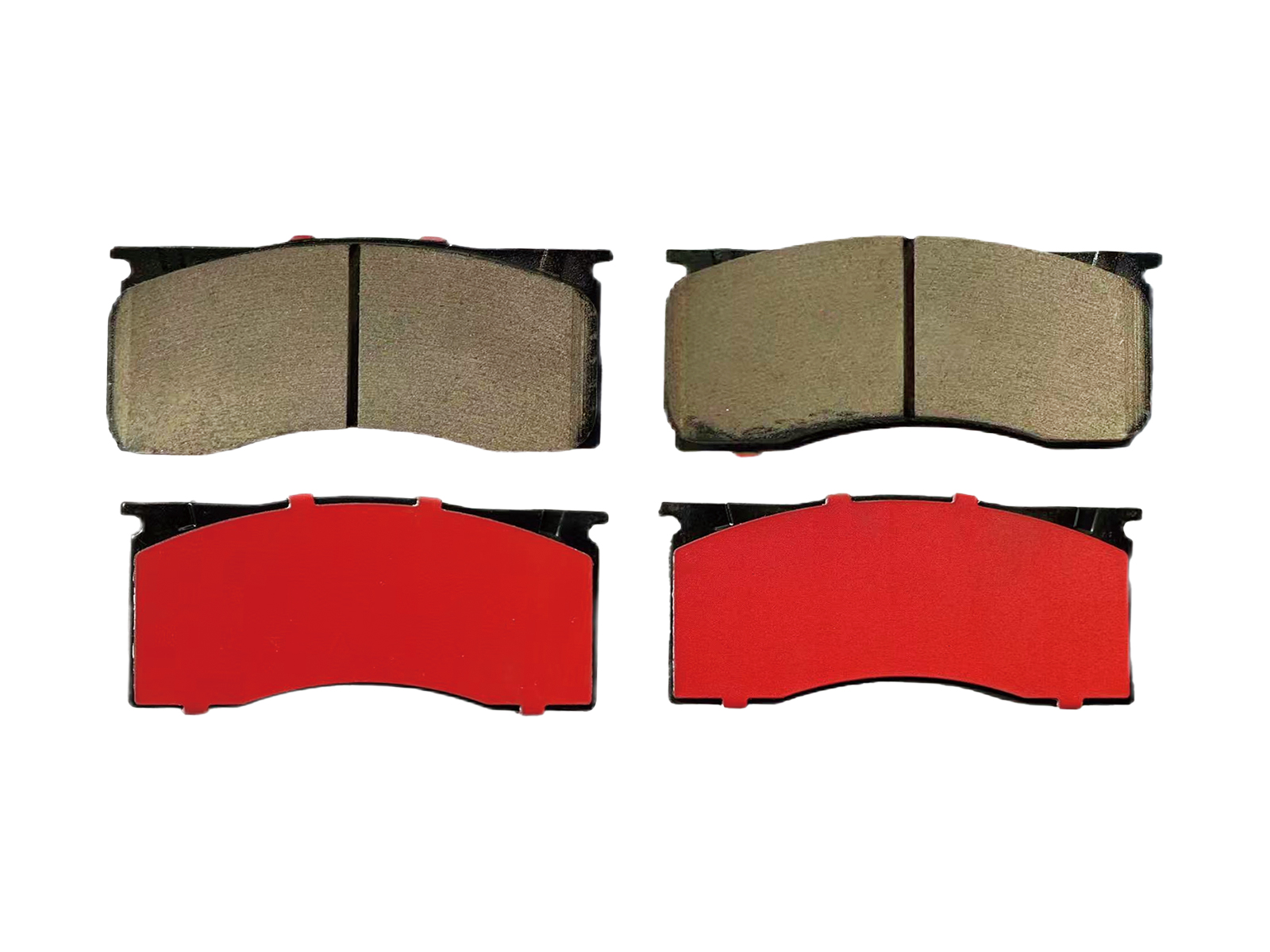

Ceramic Brake Pads, with little to no hard metal fibers, have a softer friction material. They work like a dense eraser on metal, minimizing vibration. This drastically reduces high-pitched squealing and noise—a major plus if you value cabin quiet.

They also produce far less dust, and what they produce is light gray/white. This dust lacks iron, so it doesn't bake onto your alloy wheels. Your wheels stay cleaner, longer.

Metallic (Semi-Metallic) Brake Pads are the opposite. Their high metal content (steel, iron, copper) often creates more vibration and audible noise. They generate copious black, metallic dust that quickly blackens wheels and is tough to clean.

2. Performance: Brake Feel & Heat Resistance

Here, their different "personalities" shine.

Ceramic pads offer linear, progressive braking. Pressure on the pedal gives a smooth, predictable increase in stopping power. This provides excellent control and comfort, ideal for stop-and-go traffic.

Their key strength is heat resistance (fade resistance). Under repeated or sustained braking (like long downhill drives), they maintain a more stable performance, adding a safety margin.

Metallic pads typically have a higher initial "bite." They deliver a more immediate, aggressive braking response with light pedal pressure—a feel favored by performance-oriented drivers. They excel at delivering strong power in short, hard stops.

3. Cost Analysis: Lifespan & Total Expense

The financial picture plays out over time.

Ceramic pads are generally more wear-resistant, lasting 30% to 50% longer than comparable metallics. This means fewer changes. Crucially, their rotor-friendly material significantly extends the life of your more expensive brake rotors. While the initial price is higher, the total long-term cost for pads and rotors can be lower.

Metallic pads win on upfront price, making them a common factory and budget-friendly choice. However, they wear faster and may accelerate rotor wear, potentially leading to more frequent and costly rotor replacements down the line.